Waterjet Cutting uses a high-pressure stream of water, sometimes mixed with abrasive particles, to precisely slice through various materials. It’s guided by CNC technology to ensure accurate and clean cuts without heat damage.

Oct 14, 2024 |

Waterjet Cuting

Accurate Cutting Service offers standard cutting solutions with Waterjet Cutting Machine. This advanced Water Jet Cutting method has revolutionized the way materials are processed across various sectors. With its ability to deliver precision, versatility, and eco-friendliness, the Waterjet Cutting Process is essential for optimizing production across industries.

Waterjet Cutting is a precise and powerful method of slicing materials using a high-pressure blast of water, sometimes mixed with an abrasive substance. The process begins with water being pressurized up to 60,000 psi or more, then forced through a small nozzle to create a concentrated, high-velocity stream. For softer materials like rubber or foam, pure water is used. For harder materials like metal, stone, or glass, abrasive particles such as garnet are added to increase cutting power.

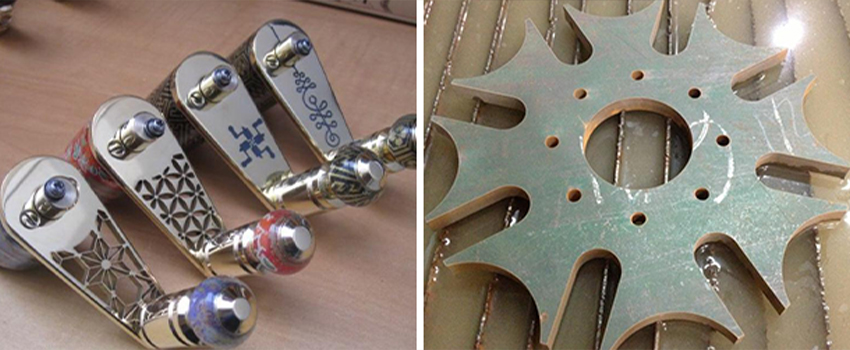

This high-speed jet erodes the material along a programmed path, guided by CNC (Computer Numerical Control) technology, ensuring excellent accuracy and minimal material waste. One major advantage of Water Jet Cutting is that it does not produce heat, eliminating the risk of thermal distortion or heat-affected zones. It's an eco-friendly, cold cutting process suitable for complex shapes and delicate designs, widely used in aerospace, automotive, construction, and residential decor.

Waterjet Cutting uses a cold cutting process, which avoids heat damage. This eliminates burrs, dross, or heat-affected zones (HAZ) often caused by other cutting methods like lasers or plasma. The result is a clean, smooth edge ready for use without the need for additional grinding or finishing—saving time and preserving the material’s integrity.

Modern Waterjet Machines support multi-axis cutting, allowing them to create 3D shapes, bevels, and intricate angles. This enables manufacturers to cut curved, sloped, or irregular surfaces with precision—ideal for aerospace parts, sculptures, and custom designs. It adds creative flexibility while maintaining accuracy.

One of the key advantages of Waterjet Technology is its ability to produce exceptionally smooth finishes. It cuts without burns or rough edges, reducing the need for post-processing. The quality of the cut meets the high standards required in industries like interior design, electronics, and signage.

Waterjet Systems excel at cutting complex shapes, sharp corners, and intricate internal cutouts. Guided by CNC programming, they can replicate even the most detailed patterns with consistent quality. This makes them ideal for custom fabrication, decorative panels, and mechanical components.

Unlike other cutting methods, Waterjet Cutting Machines don’t require molds, dies, or heat shields. Setup is simple and cost-effective, especially for short-run or prototype jobs. Material changeovers are quick, minimizing downtime and allowing for flexible production.

The aerospace sector depends on Waterjet Cutting to process high-strength materials like titanium, aluminum, and composites without altering structural integrity. The cold cutting process prevents heat distortion, while Waterjet Technology ensures accurate fabrication of critical components like turbine blades and brackets.

In automotive manufacturing, Waterjet Cutting Machines are used to cut gaskets, trim interior panels, and shape body parts. The cold cutting process is ideal for composite and rubber materials, and Waterjet Systems offer flexibility for prototyping, customization, and quick production runs.

For architectural projects, Water Jet Cutting is used to create decorative tiles, intricate metal screens, and glass designs. The cold cutting process allows safe cutting of brittle materials like marble and ceramic, while Waterjet Machines enable custom patterns and high precision.

Waterjet Technology is popular in metalworking due to its ability to cut a variety of metals with precision and minimal waste. Waterjet Cutting Machines maintain material properties and eliminate the need for extensive post-processing, making them ideal for high-quality metal components.

In glass and stone fabrication, Waterjet Cutting is used for countertops, tiles, and decorative elements. The cold cutting process prevents chipping or cracking, even in delicate materials. Waterjet Systems enable complex patterns and smooth finishes essential in design-driven projects.

Waterjet Cutting Machine is becoming the first choice for residential projects due to its precision and ability to handle diverse materials. Using advanced Waterjet Technology, it can cut through stone, tile, glass, metal, and wood—all without generating heat. This cold cutting process prevents burns, distortion, or damage, preserving the beauty and durability of each material.

Whether you need custom floor inlays, designer wall panels, or elegant kitchen backsplashes, Waterjet Cutting delivers clean, intricate, and smooth results. Waterjet Machines are perfect for transforming home design ideas into reality. With the support of modern Waterjet Systems, architects, interior designers, and homeowners can easily achieve detailed, high-quality finishes tailored to any vision.

Waterjet Cutting stands out as a reliable, eco-friendly, and highly precise cutting solution across multiple industries. From aerospace to residential design, Waterjet Cutting Machine offers unmatched versatility and performance. The cold cutting process ensures safe, clean cuts without compromising material integrity, while Waterjet Technology allows for intricate, complex shapes and superior edge finishes. With easy setup and minimal waste, Waterjet Systems are cost-effective and adaptable to both industrial and creative applications. For those seeking quality, flexibility, and innovation, Water Jet Cutting is the clear first choice.

Whether it’s a residential design or industrial application, let Accurate Cutting Service assist you with expert Waterjet Cutting solutions. Call us at +91-9979228016 or email acs.cutting@gmail.com for detailed guidance and quotes.

Waterjet Cutting uses a high-pressure stream of water, sometimes mixed with abrasive particles, to precisely slice through various materials. It’s guided by CNC technology to ensure accurate and clean cuts without heat damage.

Waterjet Cutting Machines can cut a wide range of materials including metals, stone, glass, ceramics, rubber, foam, and wood, making it versatile for many industries and residential applications.

Since Waterjet Cutting uses only water and abrasives without heat, it produces no harmful gases or waste. It’s a cold cutting process that minimizes material waste and energy consumption.

Industries like aerospace, automotive, architecture, metal fabrication, and glass & stone rely heavily on Waterjet Cutting for its precision, versatility, and ability to cut complex shapes without thermal damage.

Waterjet Cutting Machines offer clean, precise cuts on delicate materials like tile, glass, and stone without heat distortion. This makes them perfect for custom home designs such as decorative panels and floor inlays.

Waterjet Cutting, Waterjet Cutting Machine, Water Jet Cutter, Water Jet Application, Waterjet Cutting Process, Water Jet, Waterjet, Waterjet Cutter, Water Cut, Water Cutting, Abrasive Jet, Cold Cutting Process, Waterjet Cutter Machine, Waterjet Cutting Solutions, Abrasive Waterjet, Waterjet Machines, Waterjet Solutions, Waterjet Technology, Advanced Waterjet Technology, Abrasive Waterjet Cutting, Waterjet Systems, Water Jet Cutting, Waterjet Mobile, Waterjet Machine, Cnc Controlled Portable Waterjet, Cnc Portable Waterjet Cut Pipe, Waterjet Cutting Service, Water Jet Cutting Service

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.